Material selection plays a vital role in ensuring the durability and performance of extruded hose fittings. Here's how:

Strength and Mechanical Properties: The chosen material should possess the necessary strength and mechanical properties to withstand the specific operating conditions of the hose assembly. Factors such as pressure, temperature, and fluid compatibility are crucial considerations. The material should be able to resist deformation, withstand internal and external forces, and maintain structural integrity over time.

Chemical Resistance: Hose fittings are often exposed to various chemicals, solvents, oils, and fuels. It is important to select materials that exhibit high chemical resistance to prevent degradation, corrosion, or chemical reactions. Compatibility between the material and the conveyed fluids or substances is crucial to ensure longevity and avoid potential leaks or failures.

Wear and Abrasion Resistance: Hose fittings may encounter abrasive environments due to friction, rubbing, or external impacts. Choosing a material with good wear resistance can help prolong the life of the fittings and maintain performance. Materials such as certain metals, reinforced plastics, or specialized coatings can provide enhanced resistance to wear and abrasion.

Flexibility and Rigidity: The material should possess the right balance of flexibility and rigidity to accommodate the intended application. It should be able to withstand bending, twisting, or flexing without cracking or losing its shape. Flexible materials can enhance ease of installation and reduce stress on the fittings, while rigid materials can provide stability and structural support.

Sealing and Leakage Prevention: Proper material selection is crucial for achieving a secure and leak-free connection between the hose and the fitting. The material should be compatible with sealing materials, such as gaskets or O-rings, to ensure a reliable and tight seal. This helps to prevent leaks and maintain system integrity.

Longevity and Maintenance: The selected material should have a long service life with minimal maintenance requirements. It should be resistant to degradation caused by aging, environmental factors, or exposure to harsh conditions. Materials that offer longevity and require less frequent replacement or maintenance contribute to the overall durability and performance of the hose fittings.

The material selection for extruded hose fittings is crucial for ensuring durability and performance. By considering factors such as strength, chemical resistance, wear resistance, environmental factors, flexibility, sealing capability, and longevity,

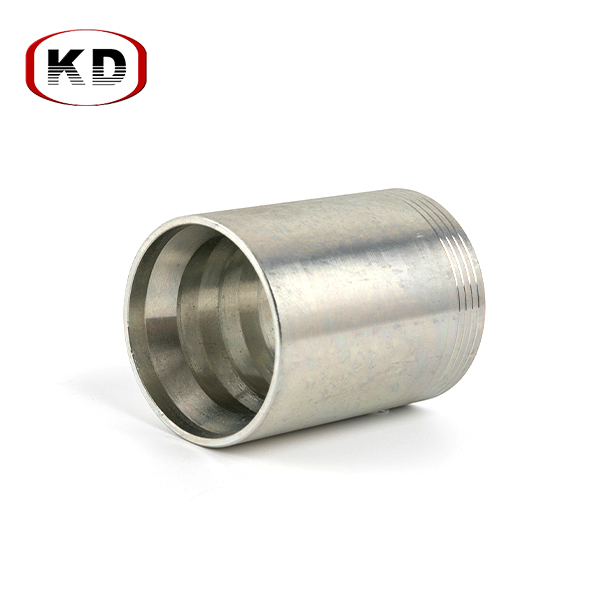

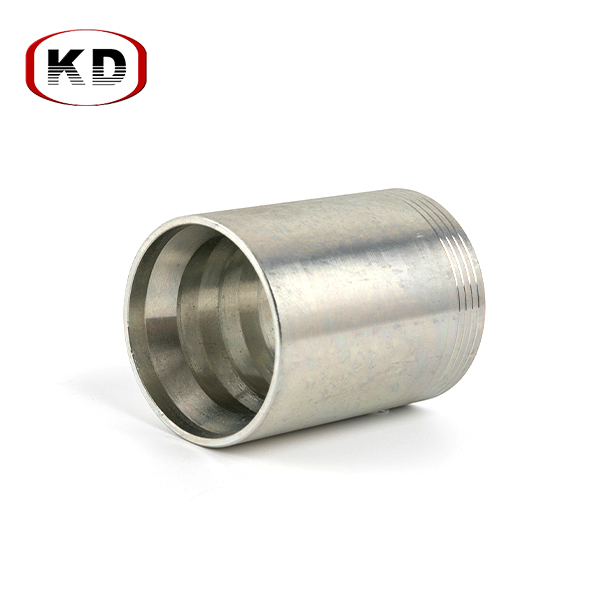

Swage Hose Fittings Manufacturers can choose materials that meet the specific requirements of the application and contribute to reliable and long-lasting hose fittings.

Coupling For 4SP Corrosion-resistant Hose play a critical position in various industries in which the transport of corrosive materials is a commonplace requirement. These hoses are particularly designed to face up to the detrimental consequences of corrosive materials, making sure a durable and lengthy-lasting solution for fluid and chemical transfer packages.

By Admin

By Admin