Swage hose fittings, also known as crimped hose fittings or hydraulic crimp fittings, differ from traditional hose fittings or connectors in how they secure the hose to the fitting and the method of attachment. Here are the key differences:

1.Attachment Method:

Swage Hose Fittings: Swage fittings use a crimping or swaging process to attach the fitting to the hose. This process involves compressing the fitting onto the hose using a specialized crimping machine, which deforms the fitting and hose end, creating a tight and permanent connection. This method ensures a secure and leak-free connection.

Traditional Hose Fittings: Traditional hose fittings or connectors typically use threaded, barbed, or push-to-connect mechanisms to secure the hose. These fittings often require additional components such as clamps, threads, or hose clamps to hold the hose in place. While they can provide a secure connection, they may not be as reliable or long-lasting as swage fittings.

2.Strength and Durability:

Swage Hose Fittings: Swage fittings are known for their high-strength and durability. The crimped connection provides a robust bond between the hose and fitting, making it suitable for high-pressure applications and heavy-duty use. Swage fittings are commonly used in hydraulic systems, industrial applications, and critical fluid transport scenarios.

Traditional Hose Fittings: Traditional fittings may not be as durable or reliable in high-pressure or high-vibration environments. They may require periodic tightening or maintenance to prevent leaks or failures.

3.Leak Resistance:

Swage Hose Fittings: Swage fittings offer excellent leak resistance due to the tight, permanent connection they create. The crimped joint ensures that there are no gaps or spaces where leaks can occur, making them ideal for applications where leakage is unacceptable.

Traditional Hose Fittings: Traditional fittings may be more prone to leaks, especially if not properly installed or maintained. The use of additional clamps or seals can help improve leak resistance, but they may not match the reliability of swage fittings.

4.Application:

Swage Hose Fittings: Swage fittings are commonly used in high-pressure hydraulic systems, oil and gas industry, aerospace, and other critical applications where safety and reliability are paramount.

Traditional Hose Fittings: Traditional hose fittings are often used in less demanding applications, such as plumbing, gardening, and general fluid transport. They are suitable for lower-pressure systems and situations where frequent disconnection and reconnection of hoses are required.

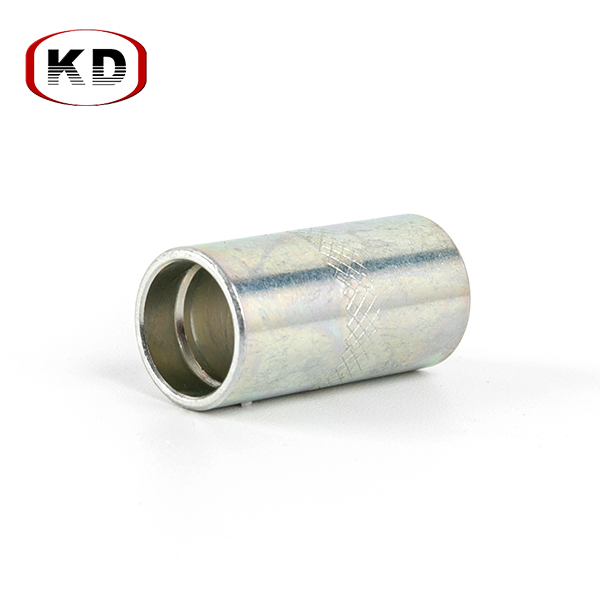

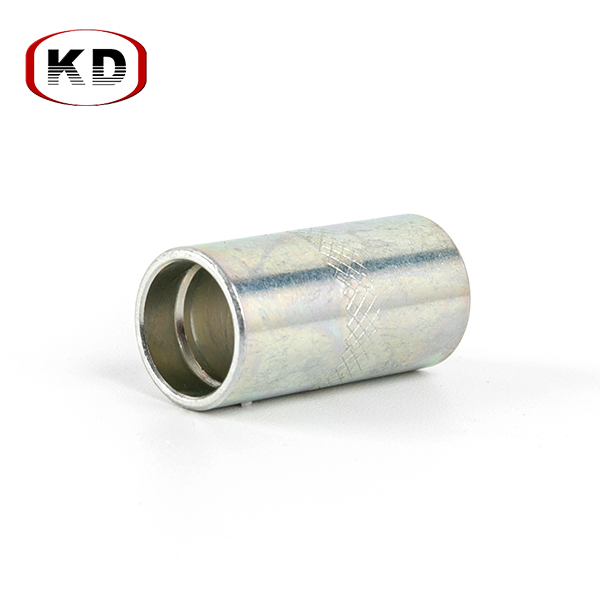

Coupling For 1TE 2TE R6 1SC SAE100R17 Hose

Coupling For 1TE 2TE R6 1SC SAE100R17 Hose

By Admin

By Admin